Post-Installation Inspection

Newly installed or rehabilitated pipelines need a thorough check before they enter service. Flotech Environmental's post-installation inspection (PII) in Florida gives project teams clear proof that each line performs the way it should. We verify alignment, grade, structural condition, and flow so the system starts strong and avoids early failures.

Our post-construction pipe inspection in Miami, Orlando, Tampa, and the surrounding regions helps teams identify issues that commonly emerge after installation. Debris left in the pipe, small alignment shifts, incorrect bedding, or unnoticed cracks can lead to sinkholes, backups, ground settlement, and costly warranty disputes if left unaddressed. We document findings clearly to help teams sign off on work with confidence and move the project forward without delay.

New Construction Doesn't Guarantee System Readiness

Freshly installed pipe systems face immediate pressure from Florida's conditions. Soil shifts after heavy rain, construction traffic compacts the backfill unevenly, and sand moves into places it doesn't belong. These factors strain new pipelines before the site opens. A line may look finished from the surface, but hidden issues inside the pipe can disrupt service as soon as the system goes live.

Our post-installation inspections catch problems that go unnoticed during construction.

Newly constructed sewer systems - including laterals, mains, manholes, and building connections - can contain hidden deficiencies that are not visible once backfill and surface restoration are complete. Construction debris left in the system, minor alignment shifts during backfilling, improper pipe bedding, joint separation, or small cracks introduced during installation can compromise system performance from the outset.

When these issues go undetected, they can lead to backups, restricted flow, ground settlement, surface depressions, or sinkhole development. In multi-building developments, early system failures often impact multiple structures at once and may result in operational disruptions, safety concerns, and costly warranty or liability disputes among owners, contractors, and developers.

Post-installation inspection provides documented verification that the sewer system was installed correctly, is structurally sound, and is free of obstructions before warranty periods expire and full occupancy begins. This process supports accountability, protects long-term infrastructure investment, and significantly reduces the risk of unexpected failures after the system is placed into service.

Our Post-Installation Inspection Process

We follow a structured sewer lateral inspection framework that gives teams a clear picture of how newly installed pipelines perform. Each step is designed to confirm installation quality, identify hidden issues, and support project close-out without surprises.

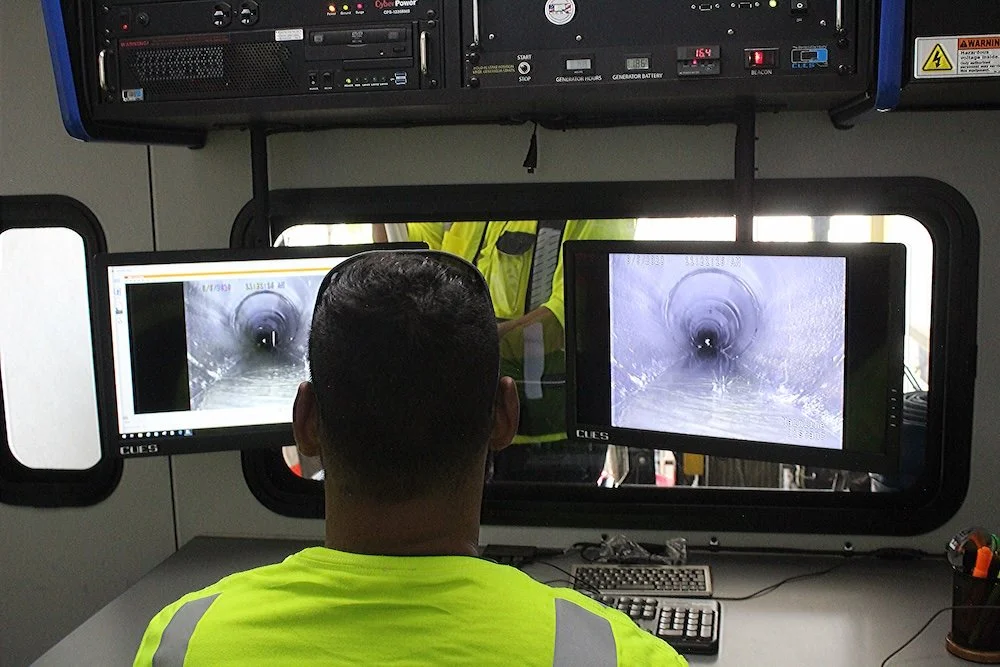

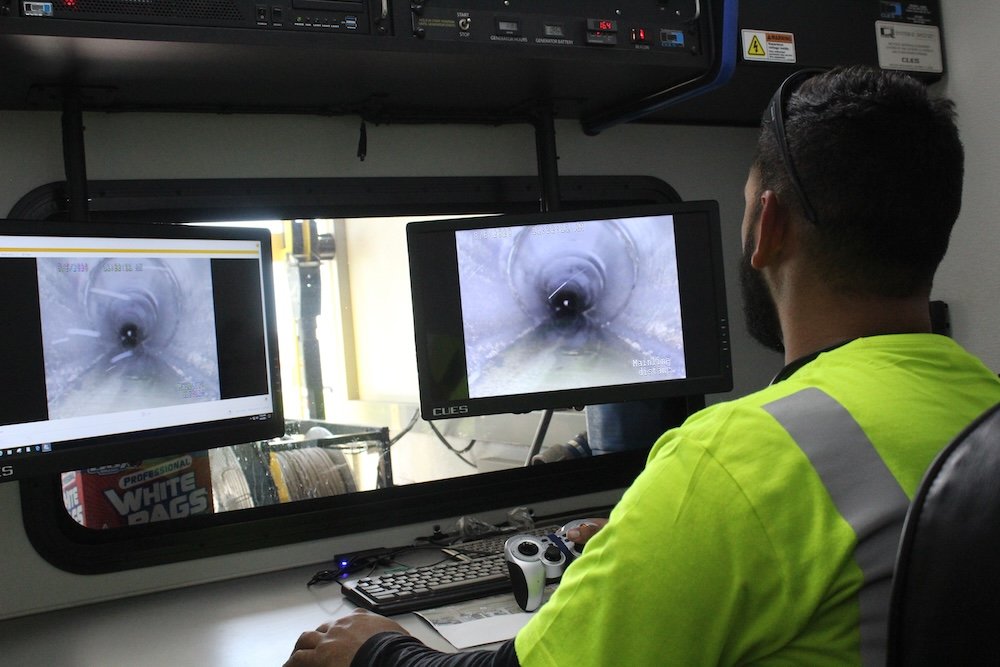

CCTV Video Assessment

Starting at an access point, we guide a camera through the entire pipeline and record every section from entry to exit. We collect a complete view of the pipe's interior and identify debris or structural concerns that appear during construction. Our crews review the footage on-site, and once again in the office, then organize the findings into clear reports so project teams can reference specific moments and understand exactly where attention is needed.

Verification of Grade and Flow

We confirm that water moves through the system without restriction. Our crews watch how the line handles flow, check grade consistency, and look for sections where water slows or collects. These tests validate the quality of the installation and show how the system will perform once the site becomes active. This step also gives project teams the insight needed to plan future maintenance and move toward project close-out.

Laser Profiling and Mandrel Testing

We use specialized tools to make sure a pipe hasn’t lost its shape under the weight of the ground. We use laser profiling to identify, accurately measure, and document deficiencies such as dips, pipe ovality, joint gap tolerances, and more. Our laser pipe inspection creates a 3D map of the pipe’s interior. For a physical check, we conduct mandrel testing, where a sized gauge is pulled through the line to ensure it hasn't been squeezed or crushed by heavy construction traffic or shifting soil. These tests provide the hard data needed to prove the system is structurally sound and ready for a long service life.

Post-Construction Pipe Inspection in Miami and Across Florida

Because Florida’s conditions can affect new pipelines almost immediately, verification before a system enters service is critical. Post-installation inspection confirms that alignment, grade, and flow remain intact after construction and before full operation begins.

-

Our NASSCO-certified local teams understand how Florida’s conditions influence pipeline performance after construction. Working across Florida every day, we know the installation standards, soil types, and field conditions that affect long-term performance. Our post-construction pipe inspection in Miami reflects the needs of coastal communities with fast-changing ground conditions and frequent storm cycles.

This regional insight helps us spot issues that might go unnoticed by crews unfamiliar with Florida's terrain, and it gives project teams a reliable path toward close-out with a system built for the state's demands.

-

Accurate post-installation inspection results keep projects moving toward completion. Our findings help contractors finalize their work and complete close-out documentation without unnecessary delays. Each report highlights the condition of the line, outlines any corrections needed, and gives project teams clear evidence that the system meets installation expectations.

Property owners rely on this documentation to confirm compliance and establish a baseline for future system care, supporting a smoother transition from construction to ongoing operation.

-

We routinely inspect new builds, site upgrades, utility expansions, and repaired pipelines. Each project brings its own challenges, and our field experience helps us recognize patterns that often appear in the early stages of service.

Confirm Your Pipeline's Performance Before the Project Moves Forward

New pipelines deserve a thorough check before they carry real flow, and our team delivers the clarity your project needs. We document every detail, confirm performance, and help crews close out work without delays or surprises. If your project calls for verification before turnover, we'll guide you through each step with clear results and practical recommendations. Contact us to schedule a post-installation inspection and move your project into its next phase.

FAQs

-

No. We access newly installed pipelines through cleanouts, manholes, or site access points, so construction teams continue working without entering private spaces. This keeps the process simple and avoids disruption during the final stages of the project.

-

Yes. We often inspect sections of a system while other parts of the site remain under construction. This approach helps teams catch issues early and avoid rework after paving, grading, or landscaping.

-

Gravity lines, force mains, storm systems, and rehabilitation projects all gain value from PII. Each system faces early stress from ground movement, heavy equipment, and site runoff, so inspection ensures the system enters service without hidden defects.